FLOOR PREP

The most important part of any coating project starts with the prep. By far the most common reason for coating failure arises from a poorly prepared surface. Whether it’s old or brand new concrete, it must be given the proper surface profile for any coatings to adhere correctly.

Whether you are tackling a coating project yourself or a contractor needing a bit of extra capacity, let us know how we can help.

PROPER EQUIPMENT

We use high quality equipment and preparation methods. Usually steel shot blasting is the preferred way to prepare a surface for most coatings. However grinding or scarifying may be the right technique depending on the job.

SAFETY

Safety is a high priority for us. No job is worth anyone getting injured. We also carry the necessary insurance required for your site.

DUST CONTAINMENT

Our process is virtually dust free. All equipment is run with high capacity dust collectors with HEPA filters. These capture nearly all of the dust created before it reaches the air.

SURFACE PROFILE

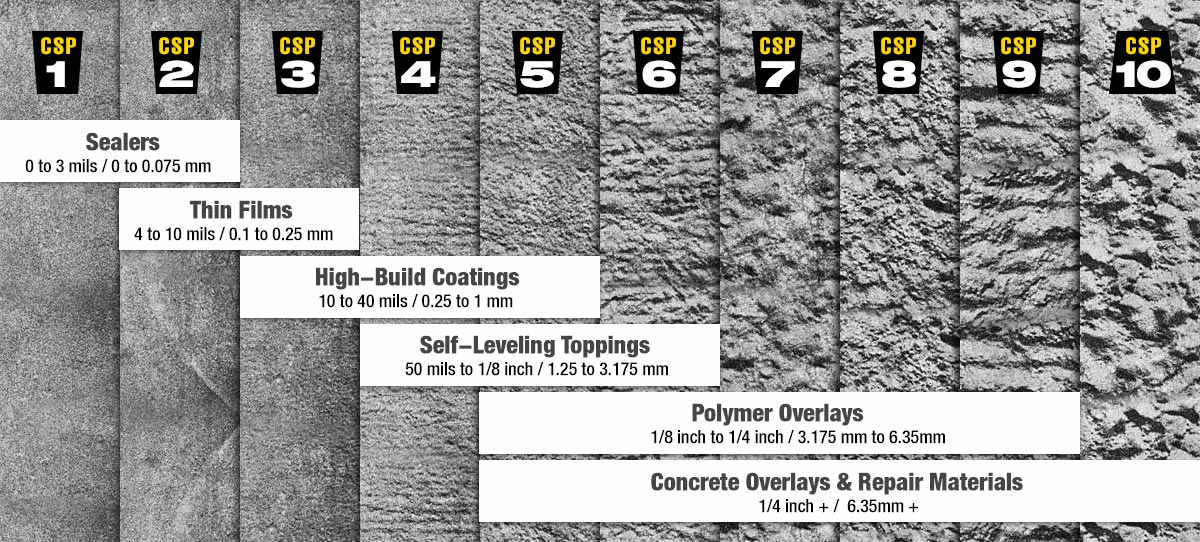

Surface profile is the most critical element to ensure a long lasting adhesion of the coating to the surface. It is defined by the International Concrete Repair Institute (ICRI) on a scale of 1 to 10.

Diamond Grinding generally produces a surface profile of CSP 2, however most coating manufacturers suggest a CSP 3-4 for proper adhesion of their coatings. Shot Blasting is able to produce a CSP of 3-4 and is therefore recommended by the ICRI as well as most coating manufacturers.